A simulative approach to obtain higher temperatures during spark plasma sintering of ZrB2 ceramics by geometry optimization

- 1 Department of Mechanical Engineering, University of Mohaghegh Ardabili, Ardabil, Iran

- 2 Department of Mechanical Engineering, College of Engineering, Boston University, Boston, USA

Abstract

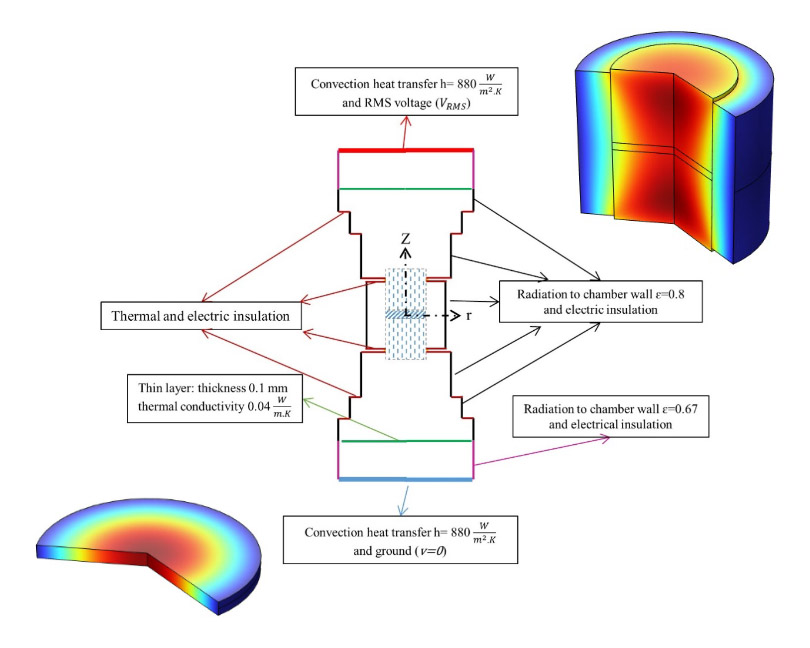

This study provides a detailed analysis of the Spark Plasma Sintering (SPS) process for Zirconium Diboride (ZrB2) ceramics, utilizing the finite element method in COMSOL Multiphysics. The focus is on understanding the temperature distribution during the SPS of a ZrB2 sample in a graphite die. Heat diffusion equations, augmented with Joule heating considerations, are utilized to simulate temperature variations within the system over time. Critical boundary conditions at the system's extremities are modeled as convection cooling. The Analysis of Variance (ANOVA) reveals that the diameter of the sample is the most significant factor influencing the peak temperature at the center of the ZrB2 sample. It is found that the sample diameter's variance accounts for a predominant impact on temperature, markedly more than other factors such as the die's outer diameter and sample thickness. Notably, the standard deviation of the temperature in the axial direction across all samples is less than 4 °C, a value that is statistically minor in comparison to the sintering temperatures, which are around 2000 °C. These findings are instrumental in providing an in-depth understanding of the SPS process, which is essential for the optimization of sintering parameters for ZrB2 ceramics.

Downloads

References

Copyright (c) 2023 Milad Sakkaki, Mohsen Naderi, Mohammad Vajdi, Farhad Sadegh Moghanlou, Ali Tarlani Beris

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.