Numerical investigation of solar collectors as a potential source for sintering of ZrB2

- 1 Department of Mechanical Engineering, University of Mohaghegh Ardabili, Ardabil, Iran

- 2 Mechanical Engineering Department Alumni, York University, Toronto, ON, Canada

Abstract

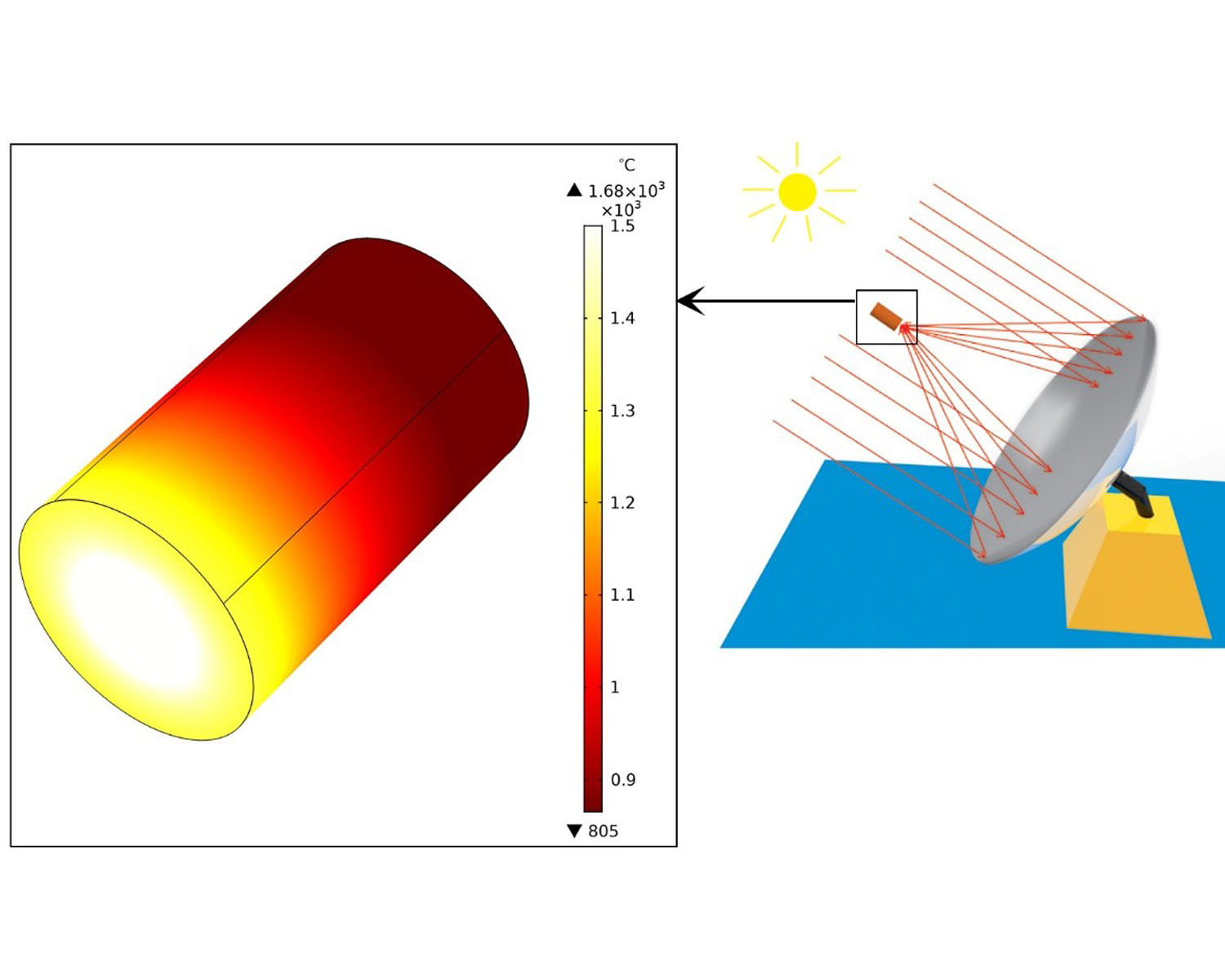

Sintering of ceramics is an energy-consuming process that needs high temperatures, therefore, in the present work; solar energy is used to produce high temperatures for the sintering aim of different materials. Solar energy concentrators increase the intensity of incident energy to the receiver provides high temperatures. Ultrahigh-temperature ceramics (UHTCs) due to their high melting point can also be a good alternative for receiver materials. In the present work, ZrB2 is introduced as an alternative material for solar receivers which can withstand high temperatures of sintering. The governing equations, including heat radiation and conduction ones are solved numerically using the finite element method. Transient heat transfer in the concentrator-collector system is investigated to check the feasibility of high temperatures needs for sintering at the receiver. The highest temperature of 1680 °C was achieved after 15 minutes at the focal point of the concentrator when the solar heat flux of 6.86 W/mm2 used for the location of the city of Ardabil in Iran. The obtained temperature can be used to sintering of some groups of materials.

Downloads

References

Copyright (c) 2021 Mohammad Vajdi, Saeed Mohammad Bagheri, Farhad Sadegh Moghanlou, Amin Shams Khorrami

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.