Ultrasonic properties of Ni–Fe–B4C cermets produced by tube furnace sintering

- 1 Afyon Kocatepe University, Faculty of Arts and Sciences, Department of Physics, 03200, Afyonkarahisar, Turkey

Abstract

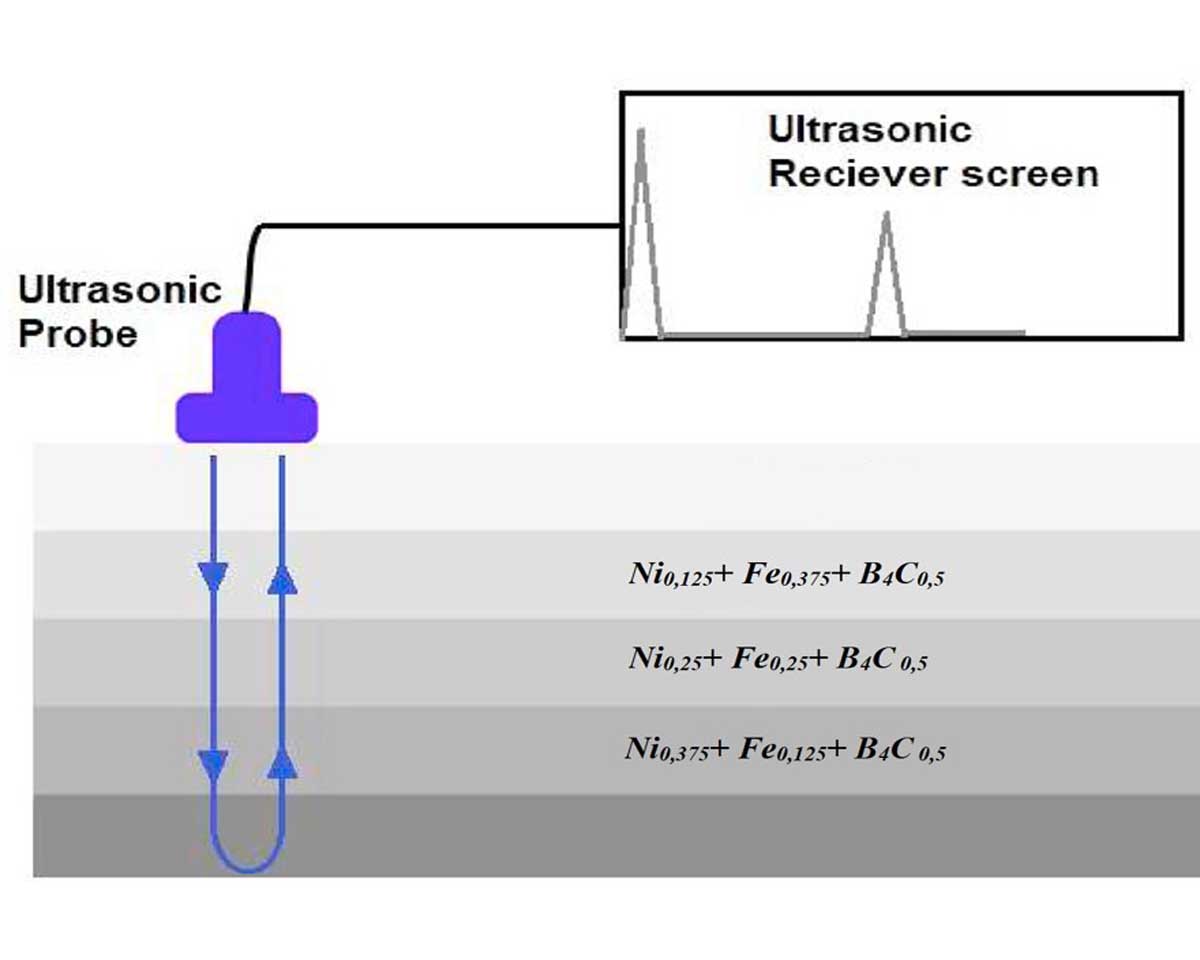

B4C–Fe–based cermets with various Ni concentrations were produced by tube furnace sintering using the powder metallurgy method. The prepared cermets were sintered at 1000 °C under the argon shroud. Ultrasonic properties such as ultrasonic wave velocities, ultrasonic longitudinal and shear attenuation values, Young's (elastic) modulus, and Poisson’s ratio were determined by the pulse-echo method using 2 MHz and 4 MHz probes. The obtained ultrasonic properties were used to characterize the properties of the samples. It was observed that ultrasonic wave velocities and Young's modulus decreased with increasing Ni concentration. At the same time, ultrasonic attenuation values and Poisson ratio increased with increasing Ni concentration. According to the results, the amount of Ni has an effective role in the structure of the cermets.

Downloads

References

Copyright (c) 2022 Vildan Özkan Bilici

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.