Synthesis and sintering of Fe-32Mn-6Si shape memory alloys prepared by mechanical alloying

- 1 Materials and Energy Research Center (MERC), P.O. Box 31779-83634, Karaj, Iran

- 2 Institute of Nuclear Physics Polish Academy of Sciences, PL-31342 Krakow, Poland

Abstract

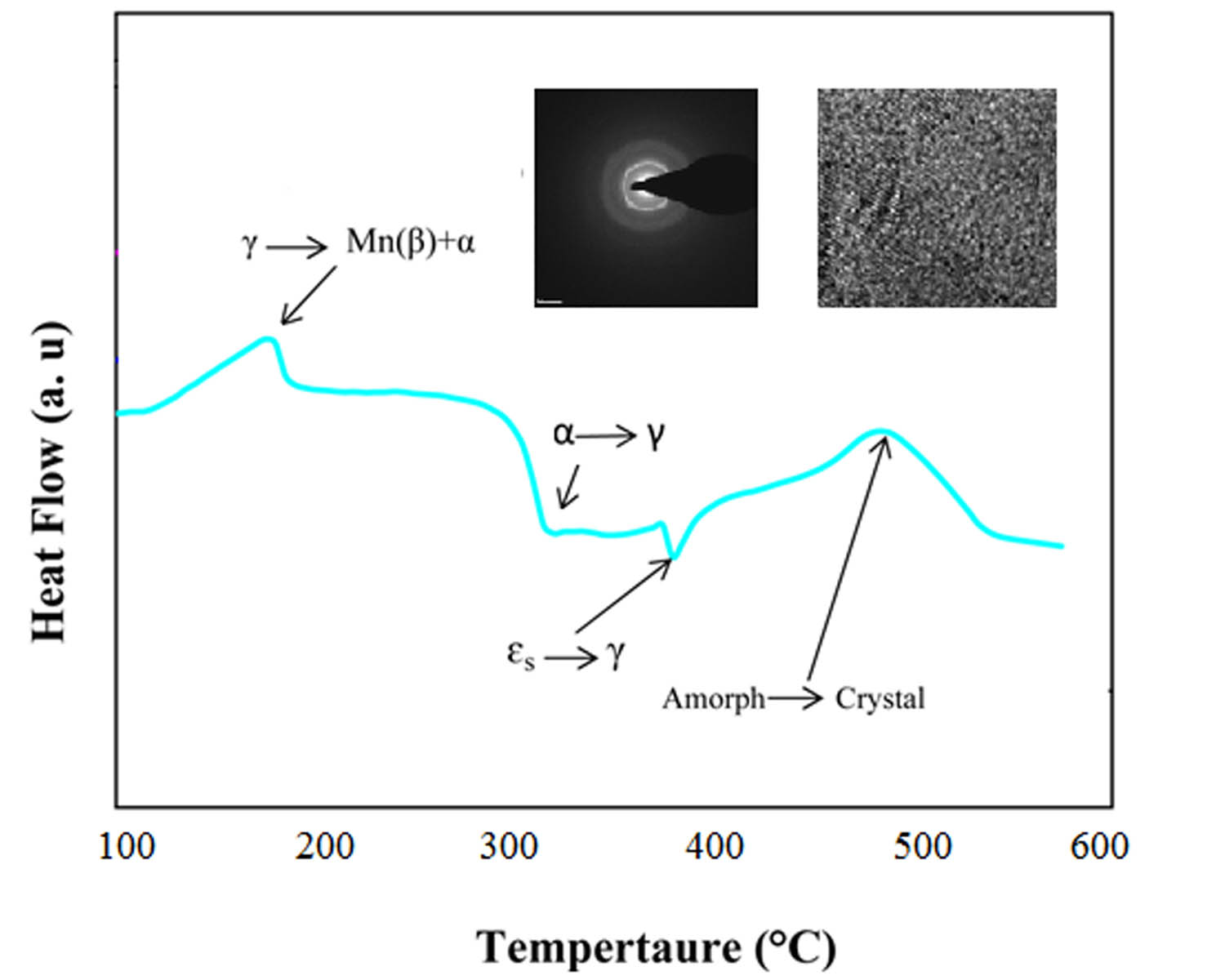

Fe-32Mn-6Si alloy was produced using the mechanical alloying (MA) process of high purity powders under an inert argon gas atmosphere. The aim of this investigation is the in-depth study of the microstructure and phase transformation during the milling-sintering process of Fe-32Mn-6Si shape memory alloys. During the milling process, a significant amount of amorphous phase was created as well the crystalline martensite and austenite phases. The amorphous phase was increased by milling time enhancement and then it was decreased due to the mechano-crystalization phenomenon. It was detected that the microhardness of the alloyed powder directly depends on the amount of the amorphous phase. Furthermore, the particle size of as-milled powder firstly decreased and then increased, when the amorphous phase cojoined gradually during the milling process the transformation of martensite into austenite. The lattice strain was increased considerably during the milling process which was a reason for martensite phase creation resulting in the high shape memory properties. The amount of pre-strain for Fe-32Mn-6Si alloy was calculated to be 3.3%. Furthermore, the optimum sintering temperature was approved to be 950 °C by reduction of the percentage of pores and suitable densification.

Downloads

References

Copyright (c) 2022 Ali Shamsipoor, Babak Mousavi, Mohammad Sadegh Shakeri

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.