Role of Si3N4 on microstructure and hardness of hot-pressed ZrB2−SiC composites

- 1 Department of Biophysics, Istanbul University-Cerrahpasa, Istanbul, Turkey

- 2 Department of Forest Biomaterials, College of Natural Resources, North Carolina State University, Raleigh, North Carolina, 27695-8005, United States

- 3 Department of Materials Science and Engineering٫ North Carolina State University, Raleigh, North Carolina, 27695-8005, United States

- 4 Department of Materials Science and Engineering, Research Institute of Advanced Materials, Seoul National University, Seoul 08826, Republic of Korea

- 5 Division of Powder/Ceramics Research, Korea Institute of Materials Science, Changwon, 51508, Republic of Korea

Abstract

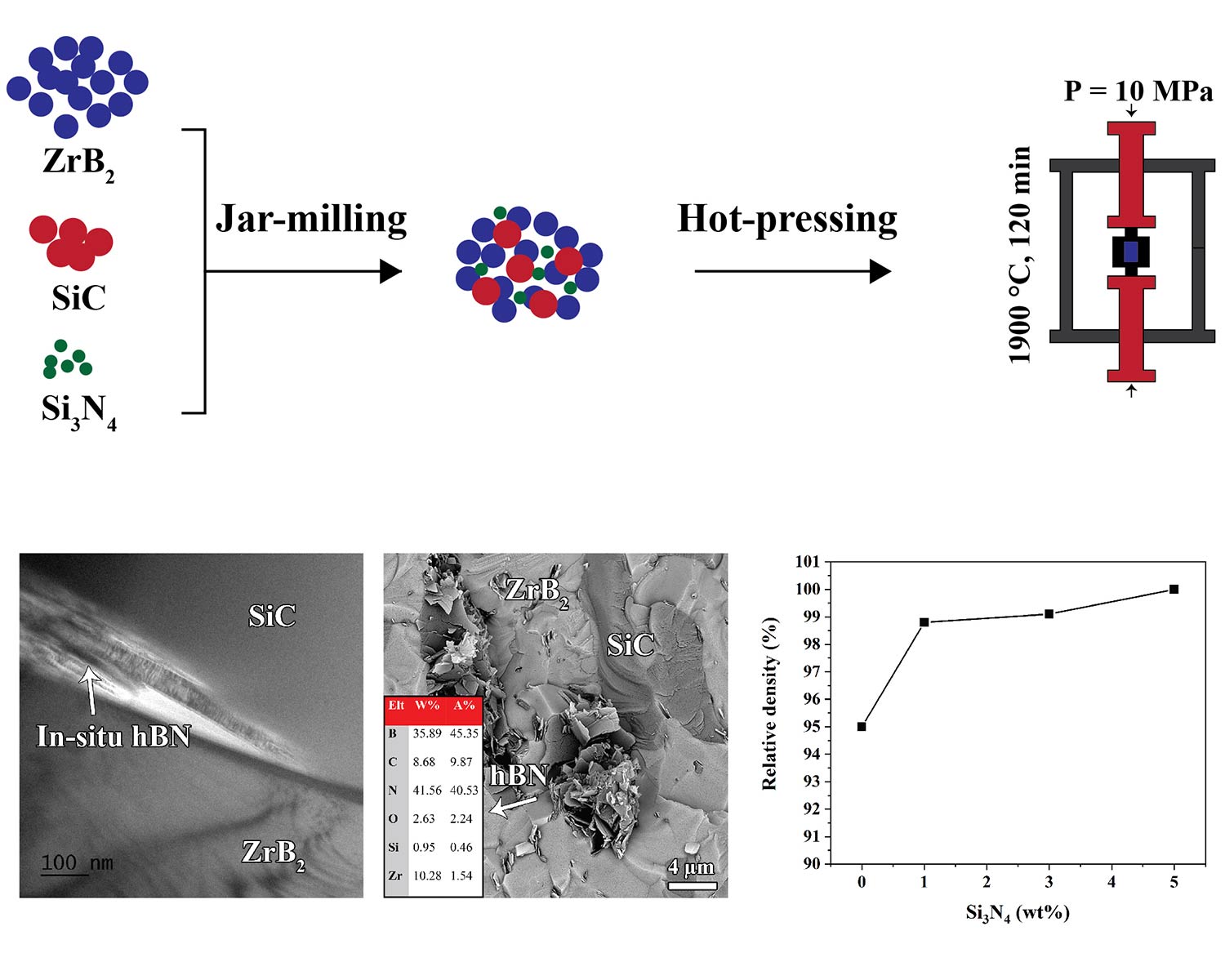

The impact of Si3N4 content on the hardness and microstructural developments of ZrB2-SiC material has been investigated thoroughly in the present investigation. Having prepared the raw materials in a jar mill, the ZrB2-SiC samples containing various amounts of Si3N4 were hot-pressed at 1850 °C. Furthermore, XRD, FESEM, and HRTEM were utilized to evaluate the microstructure of samples. The formation of in-situ h-BN was proved by the mentioned methods. Also, it was shown that the Vickers hardness of ZrB2-SiC increases up to 20 GPa in presence of 4.5 wt% Si3N4 which is 3 GPa more than the sample without Si3N4. Results show that the positive effect of increased relative density on hardness is more than the negative effect of h-BN soft phase formation.

Downloads

References

Copyright (c) 2021 Zahra Bahararjmand, Mohammad A. Khalilzadeh, Farshad Saberi-Movahed, Tae Hyung Lee, Jinghan Wang, Sea-hoon Lee, Ho Won Jang

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright

Authors are the copyright holders of their published papers in Synthesis and Sintering, which are simultaneously licensed under a Creative Commons Attribution 4.0 International License. The full details of the license are available at https://creativecommons.org/licenses/by/4.0/.

All papers published open access will be immediately and permanently free for everyone to read, download, copy, distribute, print, search, link to the full-text of papers, crawl them for indexing, pass them as data to software, or use them for any other lawful purpose without any registration obstacles or subscription fees.